What is Low-E glass?

Low-E or low-emissivity glass

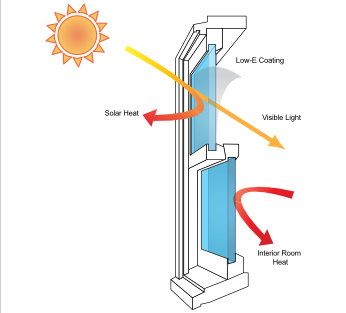

Low-E glass is standard glass with either a pyrolytic coating or a special thin metal coating on one side which reduces the heat transfer through the glass, keeping heat either in or out depending on the local climate.

Providing insulating properties in the glass to control the heat energy movement either inside or outside the building can reduce the amount of heating needed in winter or air conditioning in summer increasing the energy efficiency of your building. This style of insulating window glass still allows natural light to enter but provides a measure of solar control which is particularly useful in rooms with large expanses of glass or multiple windows.

Types of Low-E glass

Vacuum-deposited coating

The vacuum-deposited Low-E glass coating, sometimes referred to as soft-coat Low-E or splutter glass, is applied to the glass after it is formed using a vacuum chamber to deposit layers of metals, metal oxides, and metal nitrides These very thin layers increase the energy efficiency of the glass but are considered ‘soft’ and not very durable as they can be damaged by chemical cleaners or general wear and tear. For this reason, soft-coat Low-E glass is not usually suitable for single-glazed windows but functions well in double-glazed applications.

Pyrolytic coating

Pyrolytic Low-E coating, or hard-coat Low-E, is bonded to the glass during production creating a strong baked on layer. This process creates a coating which can be more than a dozen times thicker than the soft-coat alternative while providing a very hard durable layer which can be cleaned and used without fear of damaging the coating.

Both styles of coating can be used for:

- High transmission Low-E glass - allowing light but reducing the heat loss from inside the building, lowering home heating costs through winter in cooler climates.

- Low transmission Low-E glass - allows natural light in while keeping the heat out of the house or building decreasing cooling costs through summer.